Warstein, 19/04/2016 The largest manufacturers of construction and mining machinery are currently exhibiting at the bauma trade fair in Munich. This means that SIEPMANN-WERKE is being represented there too, as products from the Warstein-based forging and fitting manufacturer are often found in precisely this type of machine. The company will be adding to its list of trade fair appearances when it has its own stand and exhibit at the upcoming Hannover Messe.

Visitors to bauma 2016 were met with an impressive sight at the Volvo Construction Equipment (Volvo CE) stand over the past week as the world's largest articulated dumper was revealed to the public. The Volvo AH60 can be used to transport 55 tonnes through any rough and uneven open pit mine. According to its manufacturer, the machine increases productivity by 40% compared to what was Volvo's most powerful dumper before this model. Products from SIEPMANN-WERKE from Belecke, Warstein, are obviously not solely responsible for this performance, but they do contribute to it. In fact, four components come from the forge: the planetary carrier, taper connector, bogie stop block and bearing housing. Almost all of these are located centrally in the area of the articulated steering, meaning they are crucial parts ensuring that the 60-tonne machine operates properly and does not require a lot of maintenance work.

To be continued next week

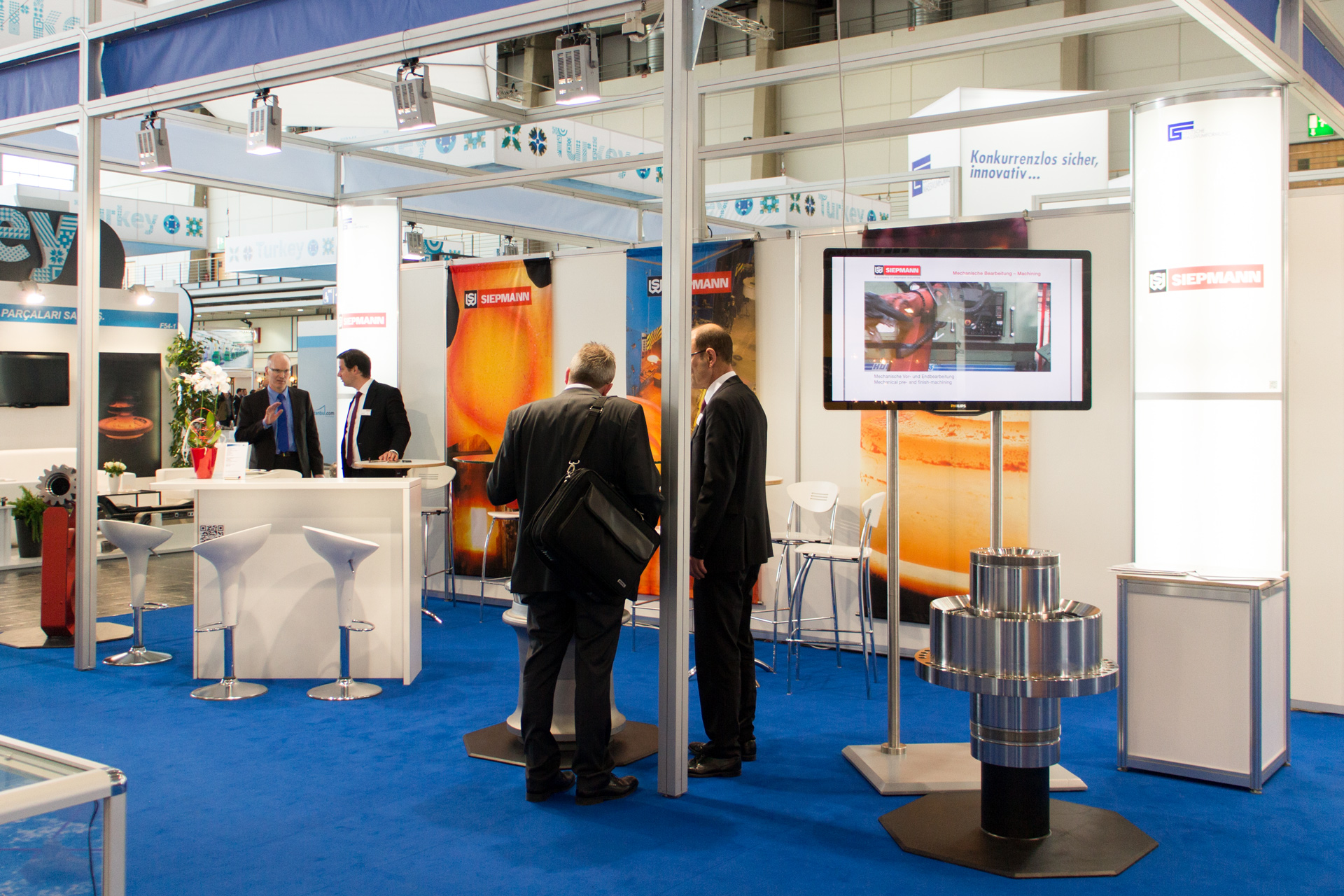

SIEPMANN will also present the bearing housing as the central exhibit on its own dedicated stand at the Hannover Messe next week in order to showcase this proven quality further afield than bauma. This component was not chosen at random given that SIEPMANN subsidiary PERSTA also contributed to it: The housing is only complete once two drop forgings have been welded together in an electron beam welding process and prepared accordingly. This welding process takes place in a vacuum and is extremely precise compared to conventional methods. Plus, it even allows for the post-processing step to be cut out altogether.

This demonstrates how SIEPMANN-WERKE is starting to focus more on quality over quantity, a strategy the company hopes will put it back on the road to success. Subsidiary PERSTA recently launched a new industrial fitting that it plans to use to enter the US market, with a benchmark contract already having been concluded within PERSTA's new market.