Quality from the heart of Warstein

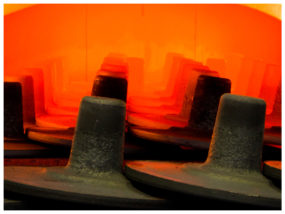

We develop, produce and market sophisticated, customer-specific product solutions made of steel. 125 years of experience that has been continuously built upon and passed down to the fourth generation of the founding family makes us real experts when it comes to drop forging, heat treatment, metallurgy, machining, unit assembly and welding processes. With an annual turnover of around EUR 85 million, some 450 employees and sales partners all around the world, we are one of the European market leaders.

Read more about the company’s history and explore our subsidiary company PERSTA Stahl-Armaturen.

Our core areas

Where we excel:

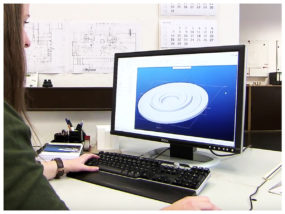

General mechanical engineering

We are among the very few specialists in forged components for general mechanical engineering and our forte is the cost-effective production of small and medium-sizes batches of exceptional quality.

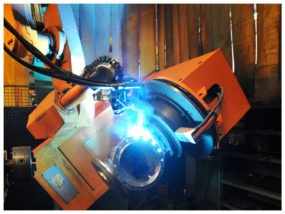

Welding technology

We have in-house specialist welding engineers for all relevant technologies, meaning we can take care of unit welding for our customers, including for safety-relevant applications.

Our products

Our products are put to use on a daily basis:

In power plants

It’s likely that when the power switch is turned on, a medium will be pushed through one of our forged fittings, given that they can be found in countless power plants all around the world.

On building sites

Diggers need to stable rather than speedy. This is something we know only too well, as some of the biggest manufacturers of construction machinery in the world use our ready-to-install hubs, for example.

In wind turbines

As a company, we make conscious choices to do our best to protect the environment. This even extends to our product portfolio, with our forgings being used in an ever-increasing number of wind turbines.

In production

Machinery is absolutely essential for manufacturing. We make sure such machines can operate by producing the relevant gear components. The size may vary, but they all guarantee smooth operation.

In raw material extraction

Natural resources are found in almost every product used on a day-to-day basis. We are involved in the extraction process – in the form of robust planetary bars for material handling, for instance.

On the tracks

Our list of products includes wheel bodies for the safest mode of transport in the world. Our rail traffic customers rely on these products to guarantee that their trains pull into the next station as smoothly as possible.

On the road

Should any problems arise, the brake is the most important component in a vehicle. It’s lucky, then, that our brake carriers can be trusted to bring even the heaviest of lorries to a standstill.

On water

SIEPMANN is leading the way, even on water. Our forged engine pistons ensure that the famous luxury cruise liner RMS Queen Mary 2 is able to sail the seven seas, for example.

Your contact